The melting shop is equipped with medium frequency Induction furnaces of 275 KW, with carrying crucibles of 250 kg & 350 kg. and temperature controlled Shell Baking furnace. We are using standard and best quality scrape to ensure the best metallurgy of casting products.

Wax Injection Moulding

Ceramic Coating

We are using fused silica, Zircon sand, and colloidal silica (water-based) binders for different applications. We have temperature Controlled and humidity-controlled Drying rooms with Dehumidifiers.

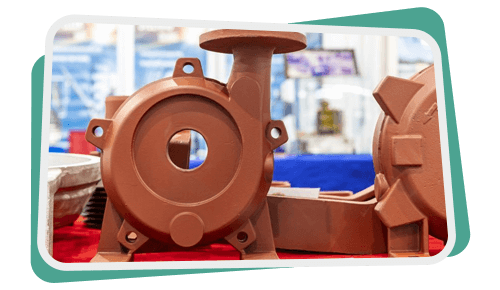

Melting

The melting shop is equipped with medium frequency Induction furnaces of 275 KW, with carrying crucibles of 250 kg & 350 kg. and temperature controlled Shell Baking furnace. We are using standard and best quality scrape to ensure the best metallurgy of casting products.

Fettling

Our fettling department is equipped with Machines for Shot Blasting, Abrasive cutting, Belt Grinding, Welding, and other machinery.

Heat Treatment

Heat treatments are used to control hardness, mechanical properties, corrosion resistance, and surface treatments. Heat treatment processes are being done as per the Customer’s requirements.

Final Inspection

We are doing a full visual inspection followed by a dimensional inspection. If the customer requirement for Radiography and other NDT then we can provide them.