- Universal Testing Machine 40 KN capacity with electronic extensometer.

- Impact Testing: Impact Testing Machine up to 300 J.

Test temp range – Ambient to -196°C. - Microscope: Microstructure Examination.

- Hardness Testing: Brinell & Rockwell Hardness Tester.

- Inter Granular Corrosion Test: Unit for IGCT practice A, B, E, C & F.

- Dye (Liquid) Penetrate Test.

- Magnetic Particle Testing.

- Radiography Testing.

- Ultrasonic Testing

- Eddy current test

- Hydro Test

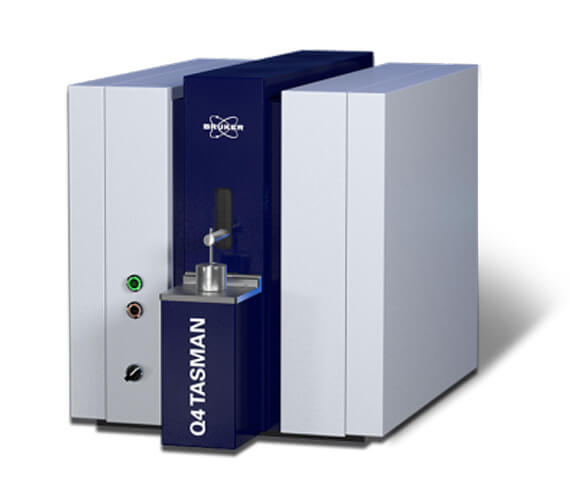

- Spectrometer : Fe, Ni, Al, Cu, CO base Spectrometer up to 45 elements with Nitrogen analysis.

- Other testing facility like, Special Microstructure, Ferrite Content, Pitting Corrosion Test and any other tests are carried out at NABL approved third party laboratory.

Those tolerance apply as general. Closer tolerance can be achieved depending up on part geometry and application of component.

- Up to 25mm: ± 0.12mm

- 25 to 50mm: ± 0.25mm

- 50 to 75mm: ± 0.38mm

- 75 to 100mm: ± 0.50mm

- 100 to 125mm: ± 0.62mm

- 125 to 150mm: ± 0.76mm