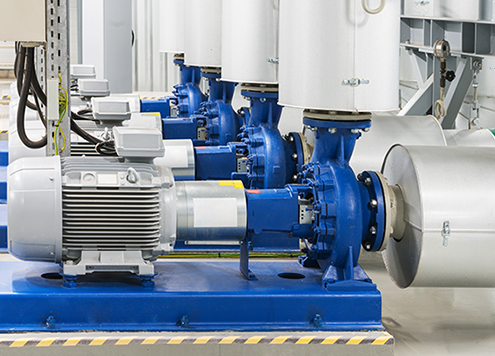

Nectar Technocast is are a leading Pump casting manufacturer for components and sub-assemblies, supplying to domestic and global markets. Started in 2009 we have huge experience, our company has proven itself as a reliable supplier of high-quality castings for pumps and pump motors. Our area of expertise at Nectar Technocast is producing premium pump casting parts. Our parts are designed to withstand the demanding requirements of different pumping applications, guaranteeing their longevity, dependability, and peak performance.

Our Products

We create an extensive range of pump casting machineries, such as:

- Centrifugal Pump Constituents: Volutes, impellers, stage casings, bowls, adapters, and housings.

- Submersible Pump Parts: Motor stools, suction casings, and diffusers.

- Multistage Pump Parts: Stage castings, diffusers, and suction casings.

- Marine Pump Components: Casings, impellers, and shafts.

Pump Casting Producing Processes

For different pump types, we can use different casting procedures. The major processes in our factory are below:

- Lost wax casting

- Aluminum die casting

- Sand casting

Rigorous Quality Control

Our quality control process starts from the raw materials reach at our facility. We conduct via reviews and tests to assure that only the best materials are used in our casting development. Throughout production, our skilled technicians makes use of state-of-the-art inspection practices and equipment to examine quality at every phase, certifying that all components exceed our severe quality requirements. From the initial design and prototyping to final assembly and shipping, our quality checks are in place to deliver steadfast pump castings that you can trust.

High-Quality Materials

At Nectar Technocast, we believe that the foundation of any positive casting lies in the materials used. We are dedicated to sourcing only the highest quality metals and alloys, confirming durability, corrosion resistance, and outstanding strength in all our products. Our extensive range of materials lets us to cater to various applications, including water, oil, and chemical pumping systems. By using premium materials, we confirm that our pump castings not only perform well below pressure nevertheless also have a long service life, eventually reducing maintenance costs and interruption for our clients.

Our Precision Engineering

Our commitment to precision engineering is what drives the effectiveness and reliability of our pump castings. Every component is cautiously designed using advanced CAD software, allowing for best performance and competence. Our skilled engineers and mechanics use cutting-edge manufacturing techniques and equipment to produce intricate designs with significant precision.

From the design part to ultimate product, we keep customer specifications and industry requirements first, ensuring that each pump casting is crafted with meticulous tolerances. Our enthusiasm to perfection means enhanced performance and effectiveness in your applications, making us the go-to choice for businesses seeking high-quality pump castings.

Why Choose Nectar Technocast?

- Industry Expertise: With years of experience in cast manufacturing, our team of specialists understands the difficulties of casting and the specific requirements of various industries.

- Customization: We offer customized solutions tailored to meet the exclusive needs of each client. Whether you require specific designs, materials, or machining processes, we are here to help.

- Timely Delivery: We value your time. Nectar Technocast are the best Pump casting manufacturer they pride itself as we on its ability to offer high-quality products promptly without losing quality.

- Customer-Centric Approach: Everything we do is centered around our consumers. To guarantee complete satisfaction with our casting goods and services, we collaborate closely with you throughout the whole process.

Contact us

Get in touch with us to talk your pump casting needs. We’ll be happy to provide you with a price and help you throughout the making process